Electrical Thermal Imaging Surveys

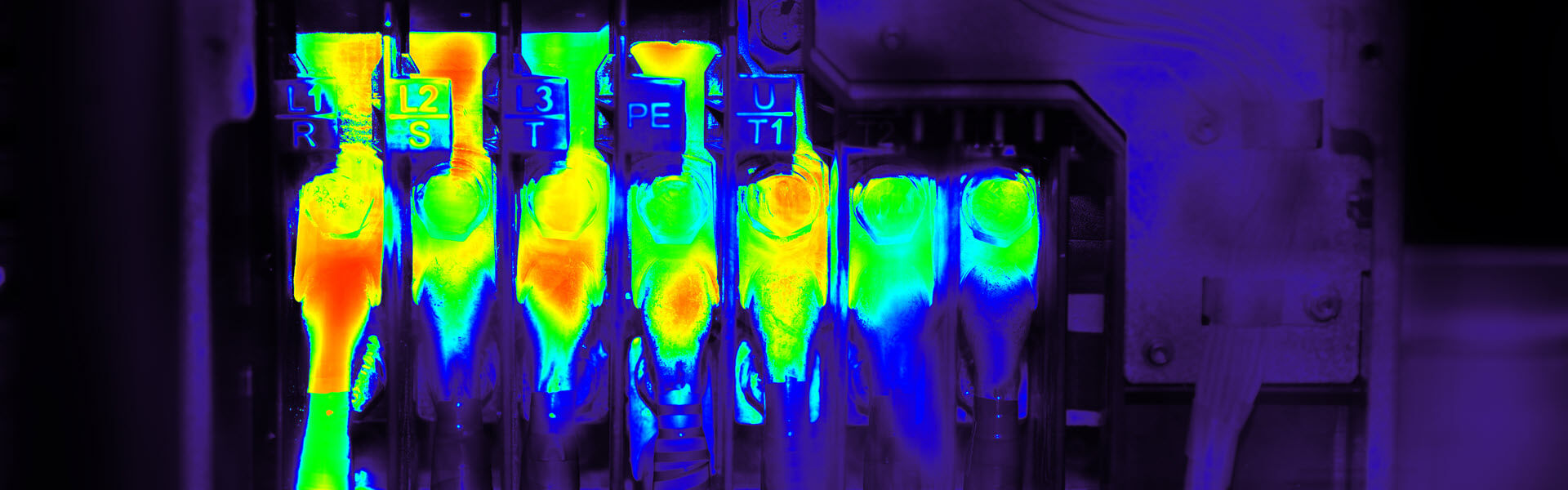

Our thermal imaging surveys of electrical systems and appliances use infrared technology for a non-invasive and non-destructive assessment.

Thermal imaging surveys for businesses in Edinburgh

As part of our facilities management and planned electrical maintenance services we carry out thermal imaging surveys and inspections for many businesses around Edinburgh.

The aim is to identify any electrical faults or overloading in cables and appliances before it becomes a serious problem – and to reduce any down time for your property’s electrical system.

Breakdowns and faults in electrical systems can lead to significant problems, these include not only financial losses due to operational downtime and the expenses of diagnosing and resolving issues, but also the dangers of fire and personal harm to members of your team.

With thermal imaging technology, we can identify potential risks in your system early, preventing them leading into bigger problems.

Thermal scanning of electrical systems

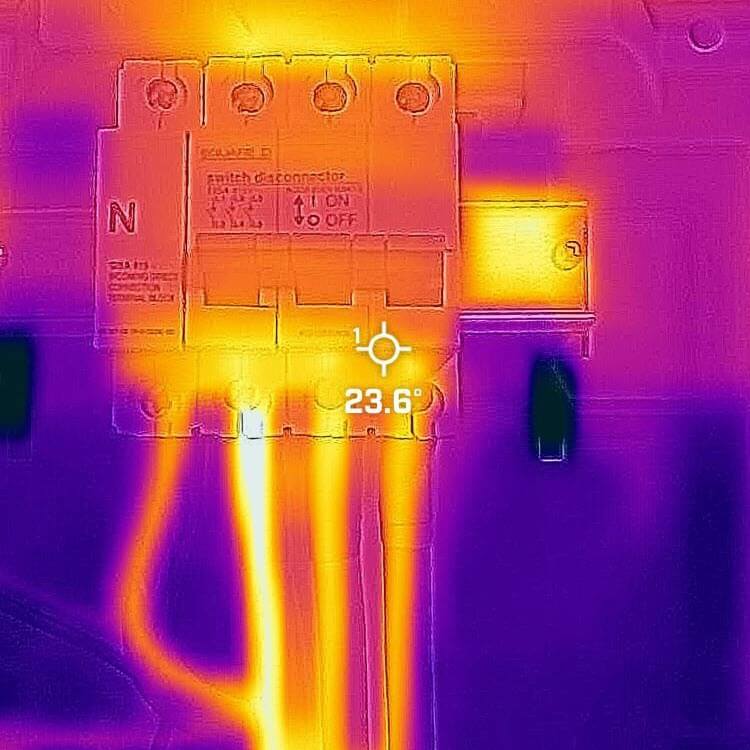

For businesses in Edinburgh, it’s essential to have regular thermal imaging surveys on key electrical components. This includes distribution boards/fuse boards, busbar systems (especially those extending to floor boxes via floor trunking), and any installed switchgear or UPS systems.

We recommend biannual inspection to identify any hot spots in connections that could cause overheating and lead to cable melting. During these surveys, we can also assess three-phase installations for load imbalance. If we detect an overload in any phase, a straightforward solution like rearranging the MCBs can effectively distribute the load across the distribution board more evenly and reducing the chance of an electrical fault or fire.

Conducting a thermal imaging survey alongside your five-yearly Electrical Installation Condition Report (EICR) test is also recommend for identifying potential electrical faults which do not show up on our multi-functional tester (Megger).

Common faults found by electrical thermal scanning

Our thermal scanning is designed to identify a range of electrical issues early on, preventing them from becoming dangerous, or causing irreparable damage.

Loose connections:

One of the primary issues we detect is loose electrical connections. These can lead to overheating and are a potential fire hazard. Our surveys pinpoint these weak spots so they can be corrected usually on the day of the survey.

Overloaded circuits:

Overloading is a common problem in many electrical systems, especially in older buildings or those with increased power demands. Our thermal imaging can identify circuits that are carrying more load than they are designed for, helping to prevent overheating and potential system failures.

Deteriorating insulation:

Over time, insulation around wires and components can degrade. This deterioration can lead to dangerous exposure and short circuits. Our thermal imaging technology can spot these insulation breakdowns early.

Unbalanced power distribution:

We often find issues with unbalanced distribution of power, particularly in three-phase electrical systems. This imbalance can strain certain parts of the system, leading to deterioration or complete failure.

Faulty components and equipment:

Sometimes, the equipment itself can be faulty, whether due to manufacturing defects or wear and tear. Our surveys can identify these faulty components before they cause larger issues.

Hot spots in switchgear and UPS systems:

Switchgear and uninterruptible power supplies (UPS) are critical for the safety and reliability of electrical systems. Our surveys detect hot spots within these systems, which can indicate potential problems.

Our Accreditations

How does thermal imaging work in electrical inspections?

Thermal imaging is a unique way to check electrical systems without having to touch them. It works by using a special camera that sees heat, which every object gives off. This camera turns the heat into a picture that shows different temperatures in various colours.

The great thing about this method is that it’s safe and doesn’t interrupt your day-to-day work. It can spot small problems, like a wire getting too hot or a part of the system working too hard, before they turn into big issues. This helps in keeping your electrical systems running smoothly and safely.

Get in touch today!

Thank you for considering our electrical thermal imaging surveys in Edinburgh. Contact us today to book an appointment, and let our award-winning team take care of you.

Address:

4-5 Parsons Green Terrace

Edinburgh

EH8 7AN

Contact:

Enquiry Form

Recent reviews

We have years of experience with electrics and our expertise shines through in what our customers have to say below.

Common FAQs for thermal imaging surveys.

You can see a list of our most frequently asked questions for carry out thermal imaging surveys on your electrical systems in Edinburgh.

Thermal imaging is a process that uses infrared cameras to detect heat variations in electrical systems and equipment. It translates these temperature differences into visual images, allowing us to identify potential electrical issues.

Thermal imaging helps in early detection of electrical faults such as overheating, overloaded circuits, or poor connections. Identifying these issues early can prevent system failures, reduce downtime, and enhance safety by preventing potential fires.

We recommend conducting thermal imaging inspections biannually. However, this may vary depending on the age and condition of your electrical installation, as well as the nature of your business operations.

No, one of the benefits of thermal imaging is that it’s a non-invasive method. Inspections can be conducted without shutting down your electrical systems, ensuring minimal disruption to your operations.

The duration of a survey depends on the size and complexity of your electrical system. Generally, a survey can be completed within a few hours.

Yes, we at ideal do thermal imaging for existing and new businesses in Edinburgh.

Thermal imaging is not capable of directly visualising electrical wires. However, it can identify areas of heat accumulation. If there is heat buildup along a wire, thermal imaging can highlight this specific area.

As seen in